Nyanzvi yakangwara mugadziri wezvinopisa conductive zvinhu

10+ Makore Ekugadzira Chiitiko

- tiger.lei@jojun.net

- +86 512-50132776

JOJUN-8600 Series Thermal Paste

★ Yakajairika Properties yeJOJUN-8600 Series Thermal Paste

| Thermal ConductivePaste | |||

| Property | Unit | Product Series | Test Method |

| JOJUN-8600 | |||

| Color |

| Bhuruu | Visual |

| Density | g/cc | 3.2 | ASTM D792 |

| Extrusion Speed@30cc, 90psi | g/min | 10-90 |

|

| ApplicationTembiricha | ℃ | -50 ~+200 |

|

| Kupisa motoKirasi |

| V0 | UL94 |

| ThermalConductivity | W/mK | 6 | ASTM D5470 |

| BreakdownVoltage | KV/mm | >5 | ASTM D149 |

| VolumeResistivity | ohm-cm | 10^13 | ASTM D257 |

| DielectricConstant | 1MHz | 7 | ASTM D150 |

★ Application

LED chip

Midziyo yekutaurirana,

Nharembozha CPU,

Memory module,

IGBT

Power modules,

Simba semiconductor munda.

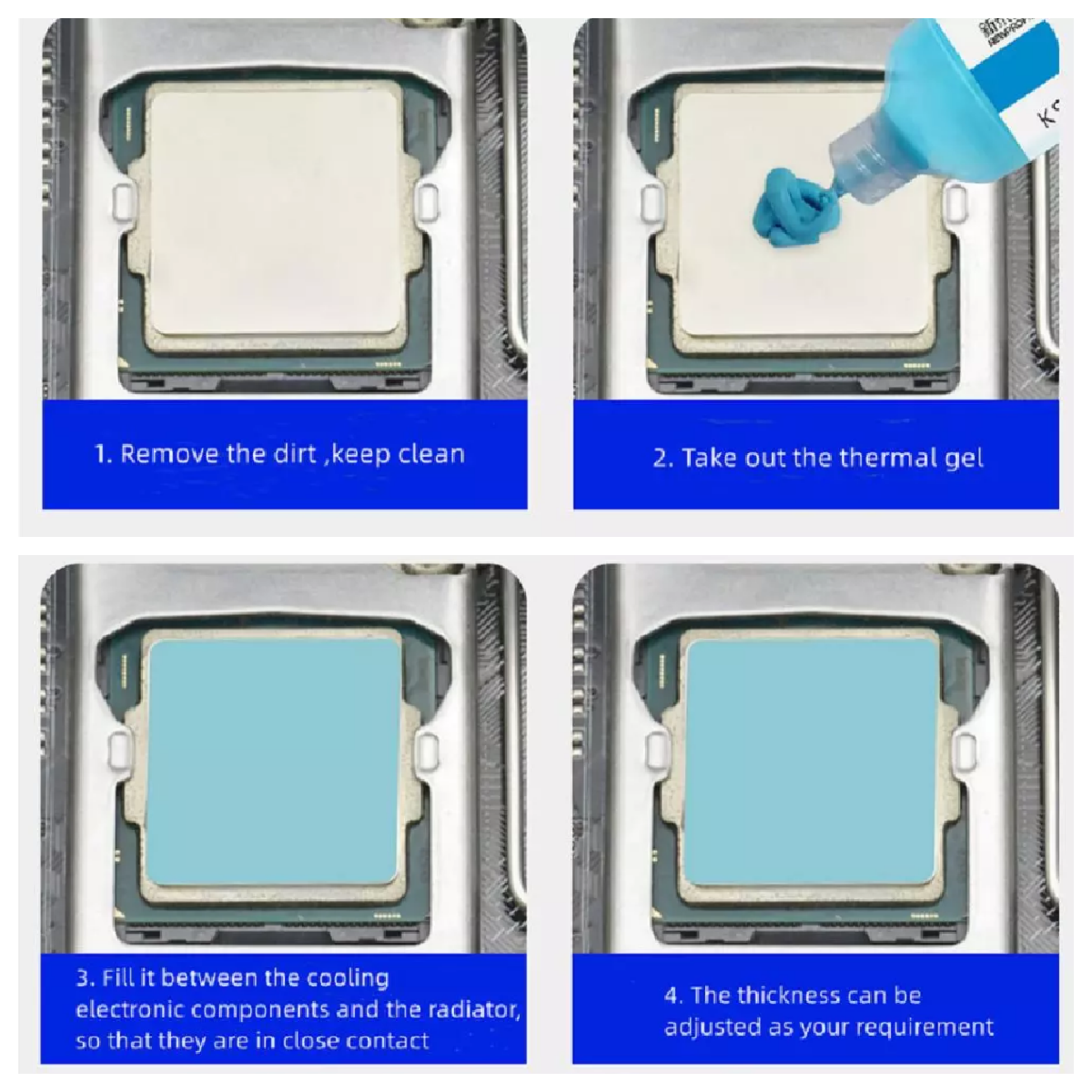

★ Kushandiswa

★ Kugadzira Maitiro

Mix Mutsa

Extrusion

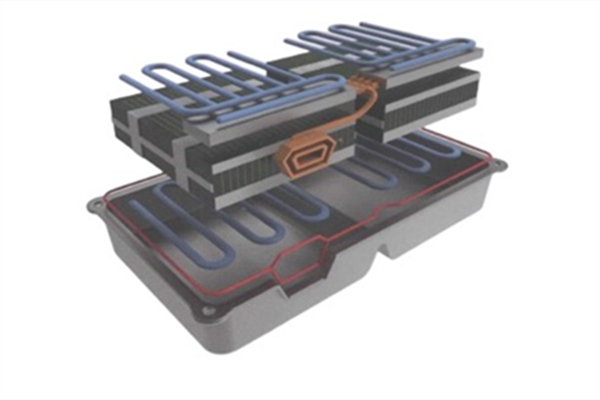

Thermal Pad Production Line

Crop

Package

Outgoing Goods

★R&D Center

Voltage Kuputsa Tester

Thermal Conductivity Tester

Kneader

Murabhoritari

★Zvinhu Uye Zvakanakira

Kuenzaniswa ne thermal pad, thermal paste yakapfava uye ine nani pamusoro pehukama.Inogona kuomeswa kune yakaderera kwazvo ukobvu, iyo inovandudza zvakanyanya kupisa kwekufambisa kushanda, uye inogona kudzvanywa kusvika 0.1mm pazasi.Panguva ino, thermal kuramba inogona kubva ku0.08℃·mu2/W kusvika 0.3℃·in2 / W, iyo inogona kusvika pakuita kwechikamu chesilicone girisi.Mukuwedzera, thermalpasteine inenge isina kuoma, mushure mekushandiswa kwemichina haizobudisi kushushikana kwemukati.

Thermal paste iri nyore kushanda nayo pane girisi inopisa.Kushandiswa kwakawanda kwesilicone girisi chidzitiro kana simbi ndiro kudhinda, kana yakananga bhurashi coating, haina hushamwari kumushandisi uye nharaunda, uye nekuda kwekumwe kuyerera kwayo, kazhinji haigone kushandiswa kune ukobvu kupfuura 0.2mm zviitiko.

Uye iyo yekupisa conductivity dhaka inopokana kuumba mune yaidiwa chimiro, kune isina kuenzana PCB bhodhi uye zvisina kujairika zvishandiso (zvakadai semabhatiri, zvikamu zvekona, nezvimwewo), zvinogona kuve nechokwadi chekuonana kwakanaka.Thermal gel ine imwe adhesion, uye haizove nedambudziko remafuta uye yakaoma, ine imwe mukana mukuvimbika.

★ Zvitupa

Zvinoumba Thermal Zvigadzirwa

-

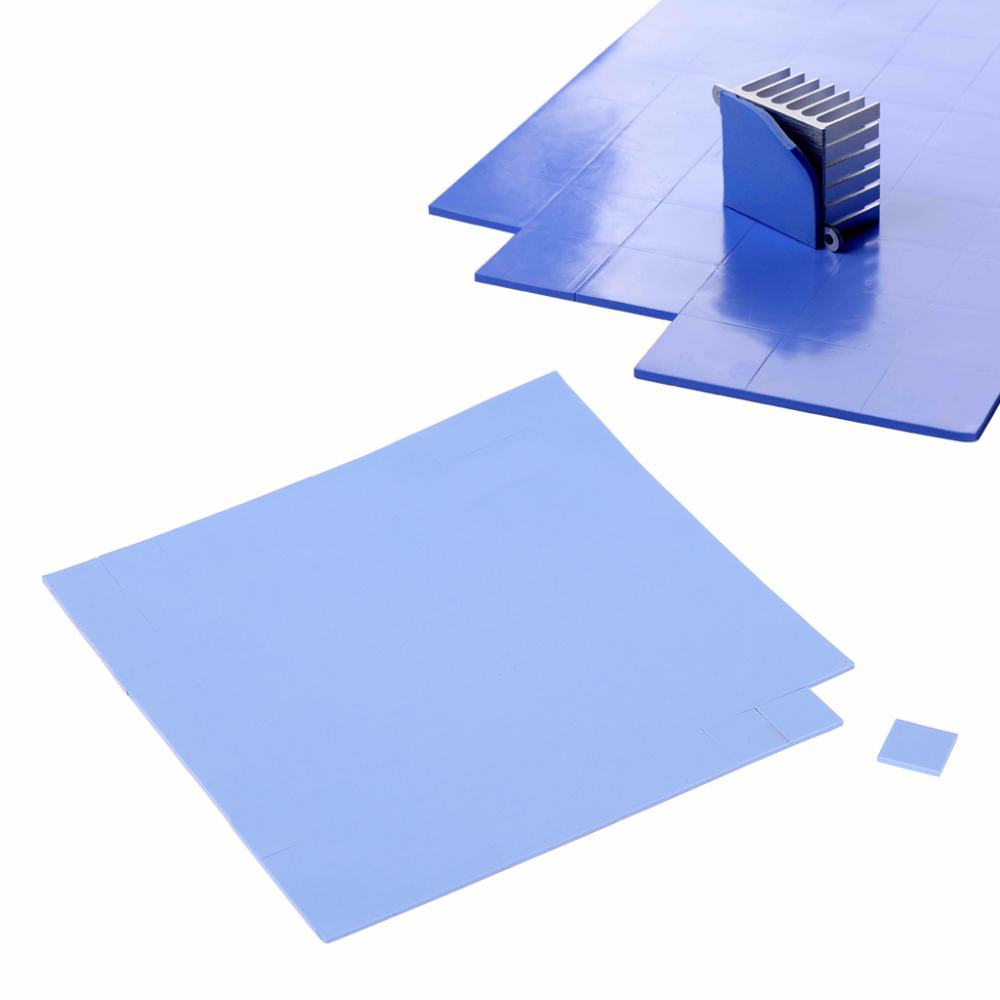

Zvimiro zveThermal Pad

1. Good thermal conductivity: 1-15 W / mK.

2. Kuomarara kwakaderera: Kuomarara kunobva paShoer00 10~80.

3. Magetsi insulating.

4. Easy kuungana. -

Zvimiro zveThermal Paste

1. Zviviri-chikamu dispensable gap filler, mvura inonamira.

2. Thermal conductivity: 1.2 ~ 4.0 W / mK

3. High voltage insulation, high compression, yakanaka tembiricha kuramba.

4. Compression application, inogona kuwana otomatiki mashandiro. -

Zvimiro zveThermal Grease

1. Kuparadzaniswa kwemafuta mashoma (kusvika ku0).

2. Chimiro chenguva refu, kuvimbika kwakanaka.

3. Kuramba kwakasimba kwemamiriro ekunze (yakakwirira uye yakaderera tembiricha kuramba -40 ~ 150 ℃).

4. Kuramba kwehunyoro, ozone resistance, kuchembera kuramba.

1.jpg)