Nyanzvi yakangwara mugadziri wezvinopisa conductive zvinhu

10+ Makore Ekugadzira Chiitiko

- tiger.lei@jojun.net

- +86 512-50132776

JOJUN-6100 Series Thermal Pad

★ Yakajairika Properties yeJOJUN-6100 Series Thermal Pad

| Zvakajairika Zvivakwa zveJOJUN6100 | |||

| Property | Unit | Product Series | Test Method |

| JOJUN6100 | |||

| Color |

| Customized | Visual |

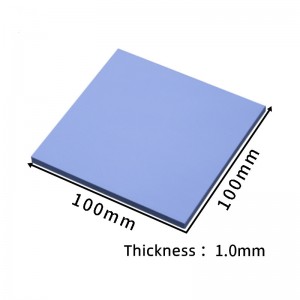

| Ukobvu | mm | 0.5-5 | ASTM D374 |

| SpecificSimba regiravhiti | g/cc | 2.8 | ASTM D792 |

| Kuoma | Shore oo | 30-70 | ASTM D2240 |

| ApplicationTembiricha | ℃ | -50 - +200 |

|

| Kupisa motoKirasi |

| V0 | UL94 |

| ThermalConductivity | W/mK | 1 | ASTM D5470 |

| BreakdownVoltage | KV/mm | >6 | ASTM D149 |

| VolumeResistivity | ohm-cm | 10 ^14 | ASTM D257 |

| DielectricConstant | 1MHz | 7 | ASTM D150 |

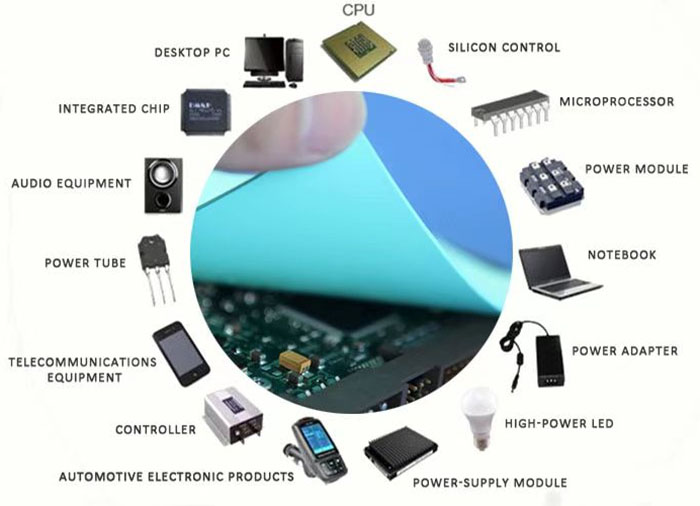

★ Application

1. LED indasitiri

Iyo thermal conductive gasket inoshandiswa pakati pealuminium substrate uye sink yekupisa.

Iyo inopisa conductive gasket inoshandiswa pakati pealuminium substrate uye goko.

2. Indasitiri yemagetsi

Shandisa kupisa conduction pakati peMOS chubhu, transformer (kana capacitor/PFC inductor) uye singi yekupisa kana imba.

3. Indasitiri yekukurukurirana

Thermal conduction uye kupisa kupisa pakati pebhodhi hombe IC uye sink yekupisa kana goko.

Heat conduction uye kupisa kupisa pakati peseti-yepamusoro bhokisi DC-DC IC uye goko.

4. Automotive Electronics Indasitiri

Thermal conductive gaskets inogona kushandiswa mumotokari yemagetsi indasitiri zvikumbiro (senge xenon lamp ballasts, stereos, mota dzakatevedzana zvigadzirwa, nezvimwewo).

5. PDP/LED TV

Heat conduction pakati pesimba amplifier IC, mufananidzo decoder IC uye kupisa sink (dzimba).

★ Kugadzira Maitiro

Mix Mutsa

Extrusion

Thermal Pad Production Line

Crop

Package

Outgoing Goods

★R&D Center

Voltage Kuputsa Tester

Thermal Conductivity Tester

Kneader

Murabhoritari

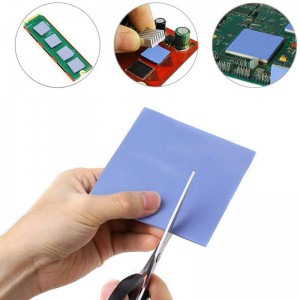

★ Yakakurumbira Sayenzi Knowledge

Thermal conductive gaskets inoshandiswa kuzadza gaka remhepo pakati pemudziyo wekudziya uye singi yekupisa kana chigadziko chesimbi.Kuchinjika uye hunhu hwayo hunovagonesa kuvhara nzvimbo dzisina kuenzana.Kupisa kunopfuudzwa kubva kumudziyo wekuparadzanisa kana PCB yese kuenda kugomba resimbi kana diffusion plate, iyo inogona kuvandudza kushanda zvakanaka uye hupenyu hwebasa hwekudziya kwemagetsi zvikamu.Iyo yekupisa conduction pad inoiswa pakati pekupisa kupisa inotonhora ndiro uye yekudziya chip kuendesa kupisa kunogadzirwa ne chip kune kupisa kunobvisa kupisa ndiro inotonhora, nekudaro ichidzikisa tembiricha yechip.Iyo yekumanikidza kushushikana ichaitika kana kupisa conduction pad kudzvanywa.Iyo compression stress inowedzera nekuwedzera kwehuwandu hwekumanikidza.Paunenge uchisarudza iyo yekupisa conduction pad, teerera kuti kudzvinyirira kudzvinyirira kweiyo kupisa conduction pad panguva yekumanikidza haifanirwe kunge yakakura kudarika yakanyanya kudiwa kumanikidzwa kweiyo inopisa chip, kana zvisina kudaro chip ichakuvadzwa.

★ Sei Sarudza Isu?

1. Professional R&D timu

Tsigiro yebvunzo yekushandisa inovimbisa kuti hauchanetseki nezve akawanda bvunzo zviridzwa.

2. Product marketing kubatana

Zvigadzirwa zvinotengeswa kunyika dzakawanda pasi rose.

3. Kudzora kwehutano hwakasimba

4. Yakagadzikana nguva yekuendesa uye inonzwisisika kurongeka kwekutora nguva yekudzora.

Isu tiri timu yehunyanzvi, nhengo dzedu dzine makore mazhinji eruzivo mukutengeserana kwenyika.Isu tiri timu yechidiki, izere nekurudziro uye hunyanzvi.Isu tiri timu yakazvipira.Isu tinoshandisa zvigadzirwa zvinogutsa kugutsa vatengi uye kuhwina kuvimba kwavo.Tiri chikwata chine zviroto.Chiroto chedu chakajairika ndechekupa vatengi zvigadzirwa zvakavimbika uye kuvandudza pamwe chete.Vimba nesu, kukunda-kuhwina.

★ Zvitupa

Zvinoumba Thermal Zvigadzirwa

-

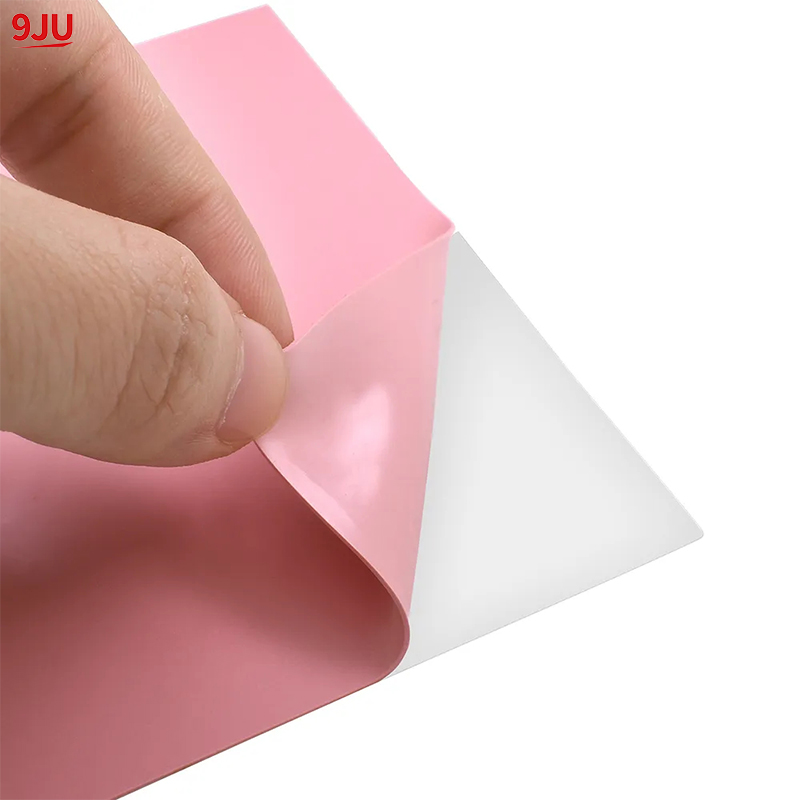

Zvimiro zveThermal Pad

1. Good thermal conductivity: 1-15 W / mK.

2. Kuomarara kwakaderera: Kuomarara kunobva paShoer00 10~80.

3. Magetsi insulating.

4. Easy kuungana. -

Zvimiro zveThermal Paste

1. Zviviri-chikamu dispensable gap filler, mvura inonamira.

2. Thermal conductivity: 1.2 ~ 4.0 W / mK

3. High voltage insulation, high compression, yakanaka tembiricha kuramba.

4. Compression application, inogona kuwana otomatiki mashandiro. -

Zvimiro zveThermal Grease

1. Kuparadzaniswa kwemafuta mashoma (kusvika ku0).

2. Chimiro chenguva refu, kuvimbika kwakanaka.

3. Kuramba kwakasimba kwemamiriro ekunze (yakakwirira uye yakaderera tembiricha kuramba -40 ~ 150 ℃).

4. Kuramba kwehunyoro, ozone resistance, kuchembera kuramba.